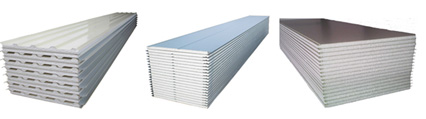

Sandwich Panel

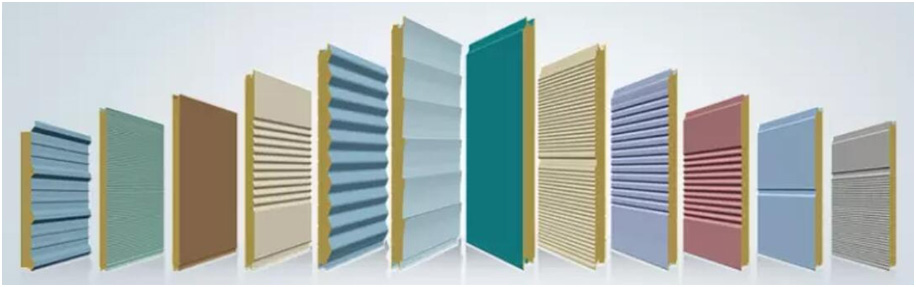

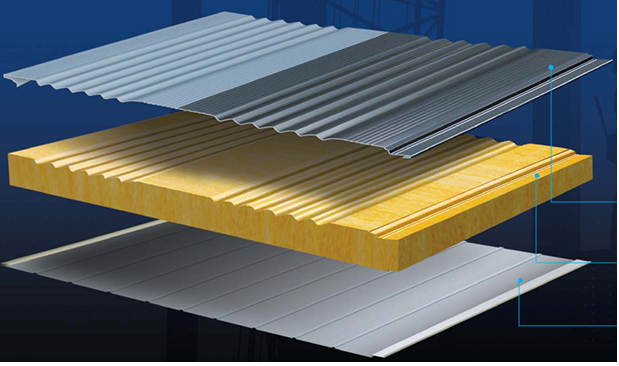

A sandwich panel is any structure made of three layers: a low-density core, and a thin skin-layer bonded to each side. Sandwich panels are used in applications where a combination of high structural rigidity and low weight is required.

The structural functionality of a sandwich panel is similar to the classic I-beam, where two face sheets primarily resist the in-plane and lateral bending loads (similar to flanges of an I- beam), while the core material mainly resists the shear loads (similar to the web of an I-beam). The idea is to use a light/soft but thick layer for the core and strong but thin layers for face sheets. This results in increasing the overall thickness of the panel, which often improves the structural attributes, like bending stiffness, and maintain or even reduce the weight.

Sandwich panels are an example of a sandwich structured composite: the strength and lightness of this technology makes it popular and widespread. Its versatility means that the panels have many applications and come in many forms: the core and skin materials can vary widely and the core may be a honeycomb or a solid filling. Enclosed panels are termed cassettes.

Product Parameters

|

Steel plates:

|

GI, PPGI, GL, PPGL

|

|

Thickness of steel plates:

|

0.4mm-0.8mm.

|

|

Thickness of core:

|

50mm/75mm/100mm.

|

|

Core material:

|

PU, PUR, PIR, GLASSWOOL, ROCKWOOL, EPS |

|

Effective width:

|

1000mm

|

|

Panel Length:

|

According to customers’ request

|

PU/PUR/PIR Sandwich Composite Panel.

As a green, environmental-friendly, light and high-strength new building cladding material, PU/PUR/PIR sandwich composite panel is a commonly used composite building material. The steel plates as outer skins offer this composite panel great strength, and the PU insulation material provides it with great thermal insulation, which is the best solution to energy conservation of buildings.

Glasswool & Rockwool Sandwich Composite Panel

Glass wool & Rockwool sandwich composite panel. The product uses high-quality glass wool& rockwool as the core material. Through the super long precision double-track curing, the product is excellent in terms of fire prevention, thermal insulation, noise reduction and environmental protection.

EPS Sandwich Composite Panel

In order to meet the suitable price requirement of buildings, the high-quality EPS sandwich wall panel. The product uses high-quality water-proof EPS as the core material. Through the super long precision double-track curing, the product is very good in terms thermal insulation, noise reduction and environmental protection.

Performance Description

Water Prevention:high-quality water-proof.

Thermal Insulation:the low coefficient of heat conductivity and the excellent node design guarantee the sealing performance and the thermal insulation effect.

Beautiful Design: multiple color , bright in color and attractive in appearance, there is no need to make the outer ornament. The panel adopts hidden-screw node design and has diversified panel effects.

Convenient Installation: Easy, flexible and fast. Compared with civil construction, it can cut down over 40% construction period.

Corrugated Steel Sheet

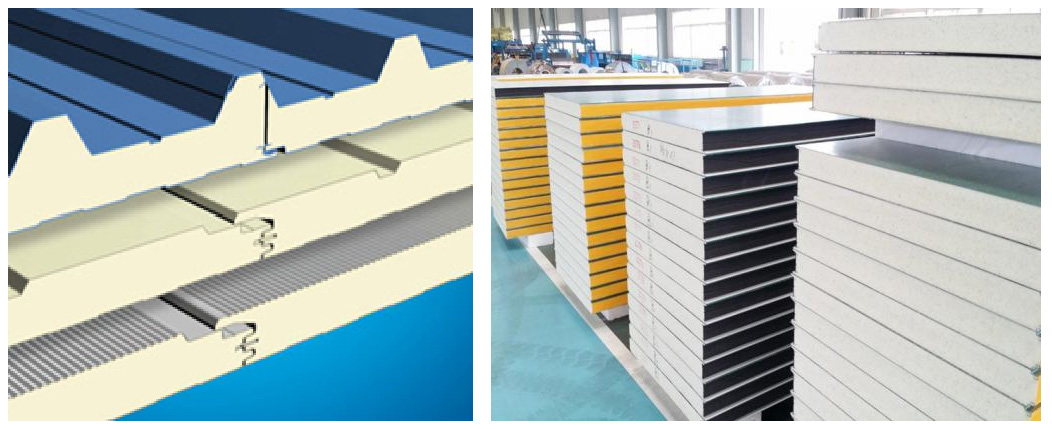

The most economical cladding for these structures is light corrugated metal sheeting, on both the roof and the external walls. These steel sheets, barely 0.5mm thick, are coated with an aluminum-zinc alloy for corrosion protection on both sides, and come with an attractive, durable paint finish on the outside. These sheets are installed over a grid of purlins, a steel member that rests on the main structural frame and supports the roofing material. In pre-engineered buildings, cold formed Z sections are the member of choice for purlins.

Before installing the sheets, contractors will install layers of insulation and vapor barriers. Rolls of glass wool or mineral wool are the most common type of insulation for such buildings. Since there is no inner wall over which to fix these layers, a layer of galvanized chicken wire mesh is first laid over the purlins. Over this, the insulation and vapor barriers are laid, and then the corrugated sheets are laid. The sheets are fixed with self tapping screws that run through the sheets and layers of insulation directly into the purlins. The purlins, chicken mesh and insulation are thus visible from below, and can be left as such or covered with a false ceiling. Polycarbonate skylights can be installed in the roof sheeting to create natural lighting.

It is common for industrial buildings to have a masonry wall upto a height of 2 to 5m. This allows doors and windows to be easily fitted, and provides security. This wall can be built behind the metal sheeting, making it invisible from the outside.

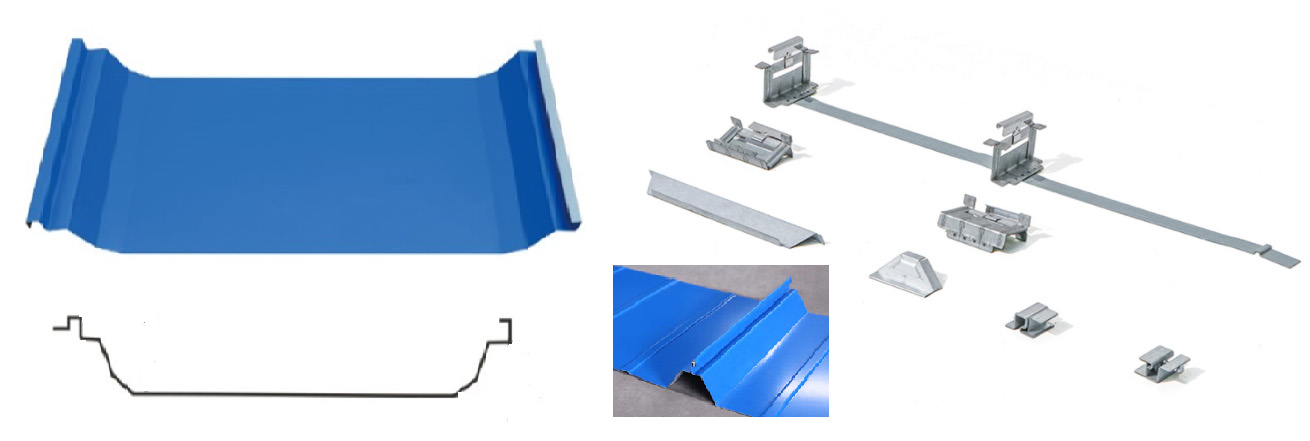

Seamlok-65 Roof System.

SEAMLOK-65 is 360 standing seaming roof system with 65mm high rib and online mastic application technology, which provides outstanding water tightness and air tightness performance. On-site roll forming is available and it can be applied to large-span roof.

Product Parameters

| Steel plates: | GL, PPGL |

|

Thickness of steel plates:

|

0.45mm-0.6mm. |

| Rib Height: | 65mm. |

| Effective width: | 485mm-500mm |

| Panel Length: | Forming at site According to customers’ request |

System Features:

360° seaming technology further improves the water tightness performance;

65mm high rib and online mastic application technology prevent water leakage:

Panel length can be tailored to meet projects requirements, and on-site roll forming service is available, which diminished needs for lengthward overlapping, lowers installation cost and difficulties, and improve installation efficiency:

Clips with movable tab allow the roof move with thermal expansion and contraction;

The high rib reduce wind noise and improve anti-deformation performance;

With other roofing systems and accessories, excellent insulation and acoustic performance will be ensured through flexible and mature design;

Roll-formed from GL & PPGL steel coil, great anti-corrosion and durability of the system is guaranteed;

Containerized special designed production line ensures product quality under unstable condition;

First class seamer with advanced motor and tooling make the excellent seaming and shorten roof erection time.

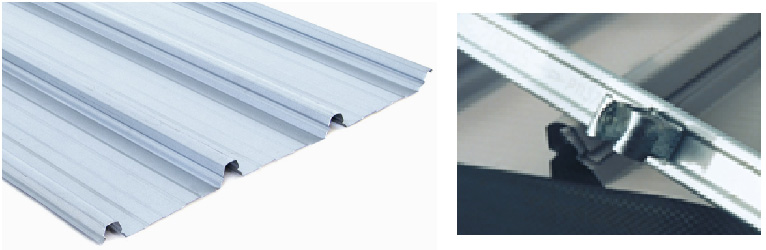

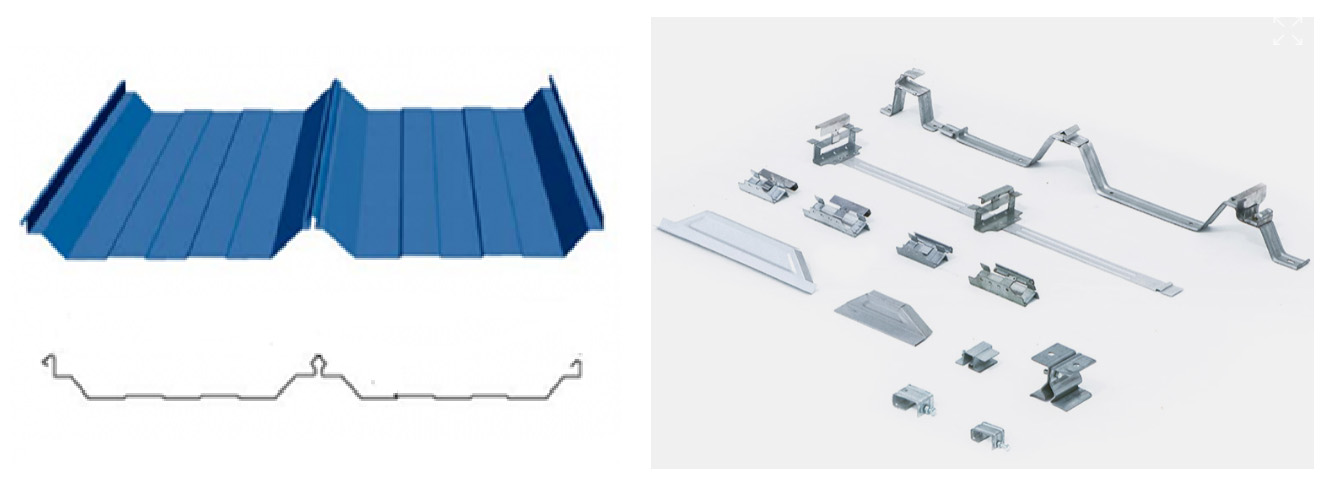

Kliplok-970 Roof System.

KLIPLOK-970 is the new generation of wide-cover, concealed-fixed cladding. It is corrugated steel roofing sheets needs to be installed by brackets, the screws are not exposed, It is easy and quickly installation, it is mostly used for on-site processing.

Product Parameters

| Steel plates: | GL, PPGL (G550) |

|

Thickness of steel plates:

|

0.45mm-0.6mm. |

| Rib Height: | 41mm. |

| Effective width: | 970mm |

| Panel Length: | Forming at site According to customers’ request |

System Features:

The coverage can be as wide as 970mm, making the profile more economical;

It has better uplift performance than any other available comparable product;

Fixed clips make installation easier and more efficient;

Improved water resistance;

High tensile steel base enhances the profiles wind pressure capability:

Customized length on request, on site processing service is available.

The appealing architectural appearance and multiple-colour choice enables different design features;

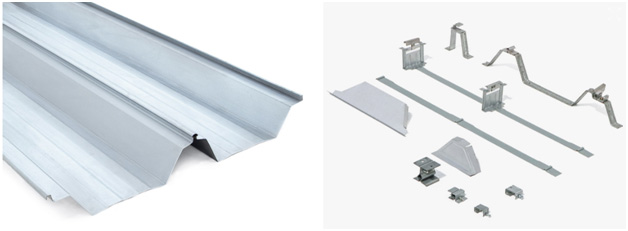

Loksem-950 Roof System.

LOKSEAM-950 is the deepth rib profile of standing seam roof system(Concealed-fixed Roof System). It is steel roofing sheets to be installed by strong brackets, the screws are not exposed, it is used for large-span roofing with low slope, the drainage effect is excellent, it is mostly used for on-site processing.

Product Parameters

| Steel plates: | GL, PPGL (G550) |

|

Thickness of steel plates:

|

0.45mm-0.6mm. |

| Rib Height: | 110mm. |

| Effective width: | 950mm |

| Panel Length: | Forming at site According to customers’ request |

System Features:

180° occlusion—Upright lock seam roofing system.

180° vertical fastening seam, waterproof and airtight.

No screw penetration on the surface of the system.

The unique sliding-sliding bracket makes the system have perfect thermal expansion and contraction compensation function.

Processed equipment cabinets to ensure accurate on-site suppression of large projects.

Lokseam-1035 Roof System.

LOKSEAM-1035 is the new generation of wide-cover, concealed-fixed cladding. It is corrugated steel roofing sheets needs to be installed by brackets, the screws are not exposed, it is used for large-span roofing, the drainage effect is good, it is not suitable for transportation, and it is mostly used for on-site processing.

Product Parameters.

| Steel plates: | GL, PPGL (G550) |

|

Thickness of steel plates:

|

0.45mm-0.6mm. |

| Rib Height: | 66mm. |

| Effective width: | 1035mm |

| Panel Length: | Forming at site According to customers’ request |

System Features:

180° occlusion—Upright lock seam roofing system.

180° vertical fastening seam, waterproof and airtight.

No screw penetration on the surface of the system.

The unique sliding-sliding bracket makes the system have perfect thermal expansion and contraction compensation function.

Processed equipment cabinets to ensure accurate on-site suppression of large projects.

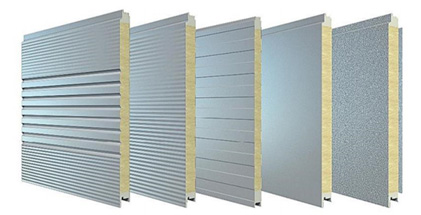

Normal Corrugated Steel Sheets.

Other normal corrugated steel sheets is more suitable for wall panels and ceiling panels. It is large in size and beautiful in appearance, and can also be used in small span roofs. And it can bring a small side, it can be used as a high-strength board.

Product Parameters

|

Steel plates:

|

GI, PPGI, GL, PPGL (G300-G550) |

|

Thickness of steel plates:

|

0.35mm-0.6mm.

|

| Number of rib: | 5rib-13rib |

| Rib Height: | 7mm-30mm. |

|

Effective width:

|

1100-1000mm |

|

Panel Length:

|

According to customers’ request

|

System Features:

Standard wall panels commonly used in industrial buildings.

It is directly connected to the secondary structure by screws and has strong wind resistance.

The wave height and trough design make the wall panel have a stronger three-dimensional effect and better appearance.

High standard, high strength fasteners provide excellent weather tightness.

High effective utilization, easy installation, economical and practical.